Cosmo it's an im3100 model.

Here was my final test fit of the actual items before I started with the paper.

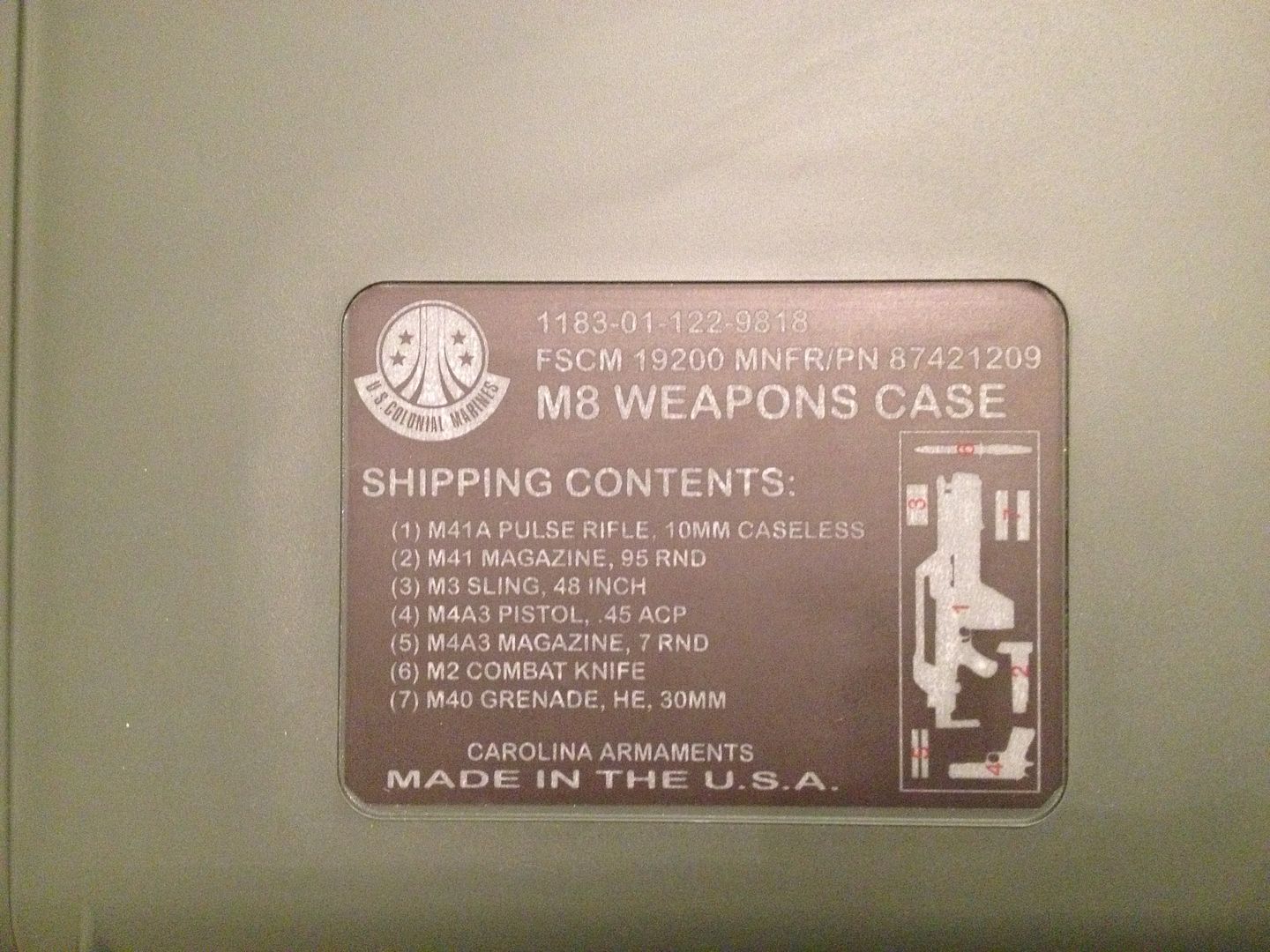

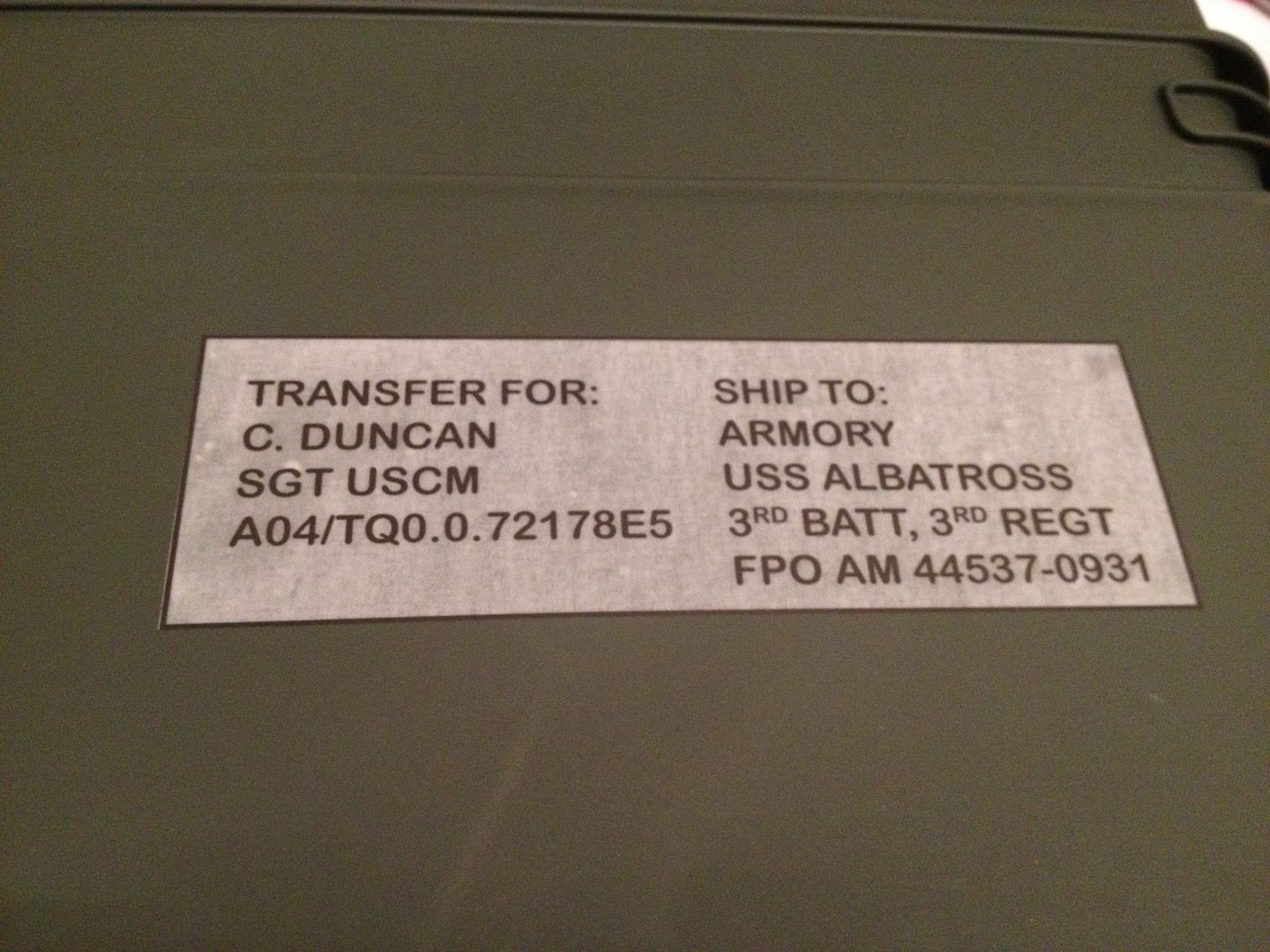

Next, I made a few stickers to put on the case. I originally wanted to use a yellow font, but the the clear isn't really clear, so it was very hard to see. I went back and remade them black and white like I did for the Armat label plates.

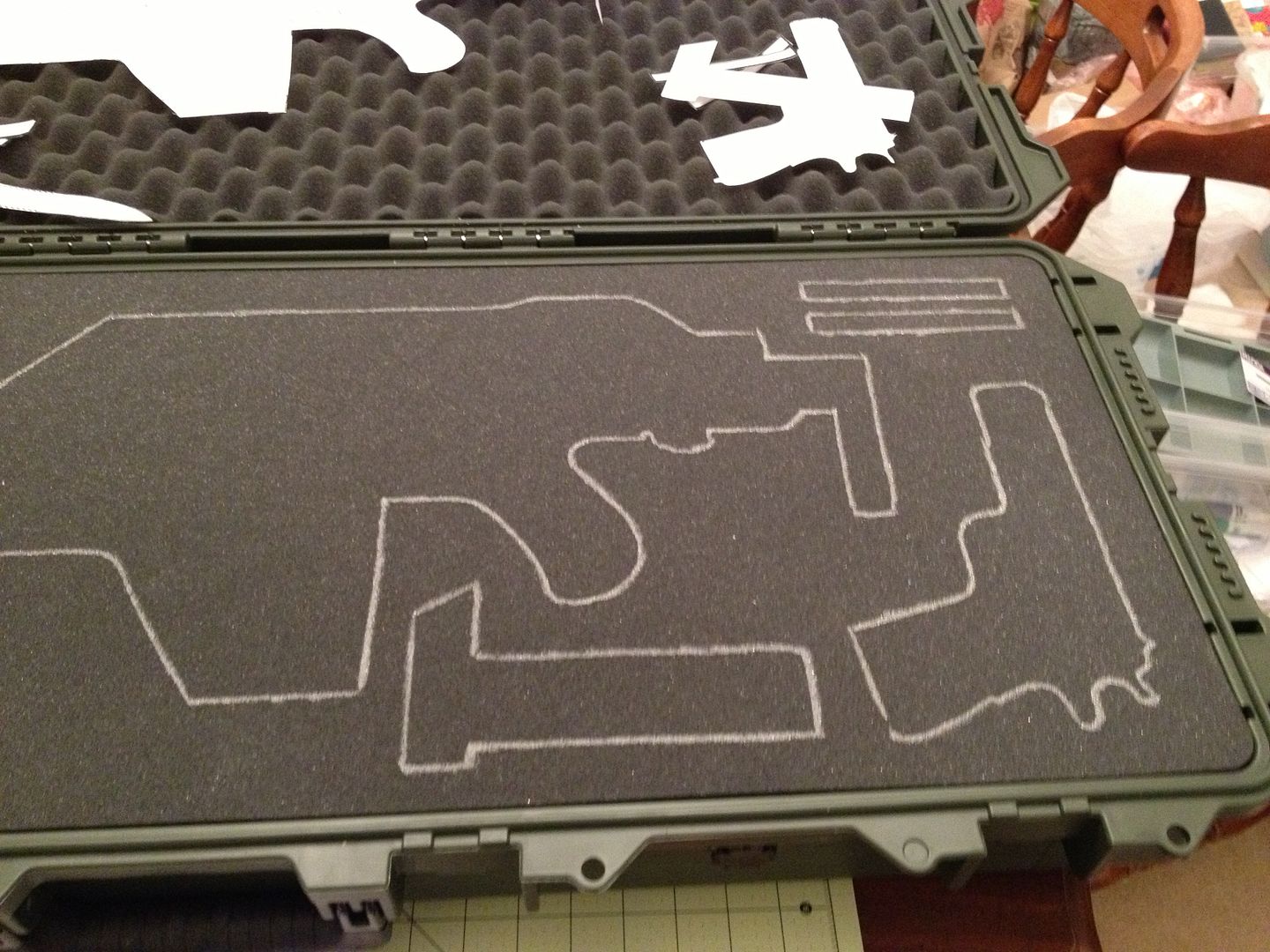

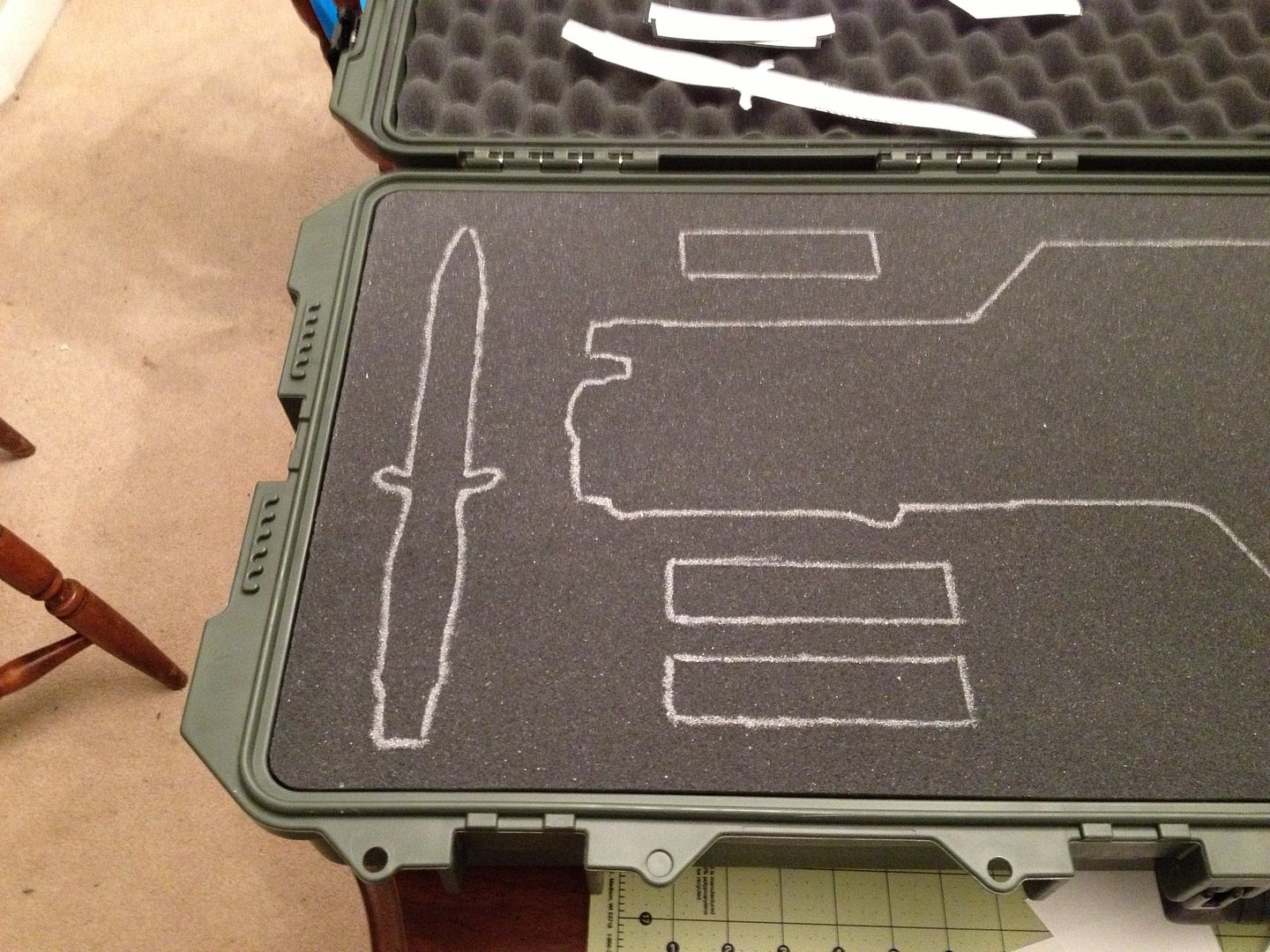

I actually think I did the stickers first just cause I was scared to start cutting the foam. lol. But it had to be done eventually. I opened the case up and put the templates down. Now, you will notice that I put them down backwards. My plan was to outline the templates with a silver sharpie. But, I didn't want to have the sharpie showing (you have to cut a little thinner than your measurements to make the foam hold the items tightly). So, I flipped the foam upside, verified it was the same on top and bottom, and then mirrored what I wanted it to look like. This way, when I cut through the foam, everything would face the direction I want but there would be no silver sharpie visible in the case.

To do the cutouts, I used a Proxxon hot wire cutter like this:

[IMG]http://www.homedepot.com/catalog/productImages/300/1c/1c09e67c-b852-49c2-935a-edb17ac92298_300.jpg[IMG]

I used a razor knife to cut a small slit in the middle of the cutout, and then I would thread the wire through the slit. Reconnect to power terminal, hot it up, and boom foam cutting time. The only difficulty was that the foam pad was too big to actually use the guides on the table, so everything was freehand. It still came out ok but it doesn't look super sharp up close.

I cut the tops off of the shotgun shell holder and filed the edges a bit. I left them red, just cause it added a bit of colour and hey, it's explosives. I also had to cut some scraps in half and make an additional layer for the Gerber knife. The mid layer foam is 1.5" thick; the Gerber got lost in it.

I've ordered an extra mag base from Evike. It should be here next week. I have another mag, so I will keep the Noble base plate one in the case for display purposes. I will go back to the original design for carrying in the PR unless Noble does another run of the mag inserts, in which case I get will get one.

I had my appointment with the CNC shop today as well. They were willing to do the work for me, so hopefully in about three weeks I'll have a nice shiny pile of machined aluminum grenades.

Charlie

_________________

"There is a clause in the contract which specifically states any systematized transmission indicating a possible intelligent origin must be investigated. On penalty of total forfeiture of shares. No money."